Understanding Inventory Counts and Inventory Management: Keys to Operational Success

In today's fast-paced business landscape, efficient inventory management is crucial for companies aiming to meet customer demands, minimize costs, and optimize overall operational performance. At the heart of inventory management lies inventory counts, a fundamental process that serves as the foundation for maintaining accurate inventory levels. In this piece, we will explore the definitions of stocktaking and inventory management, their roles in modern business, and why mastering both is essential for long-term success.

Inventory Counting: The Bedrock of Inventory Accuracy

Inventory counting, also known as stocktaking, refers to the process of physically verifying the quantities and conditions of items held in inventory. This can be done periodically—such as annually or quarterly—or more frequently, depending on the nature and scale of the business. The goal of inventory counting is to ensure that the actual physical stock aligns with the records in an organization’s inventory management system.

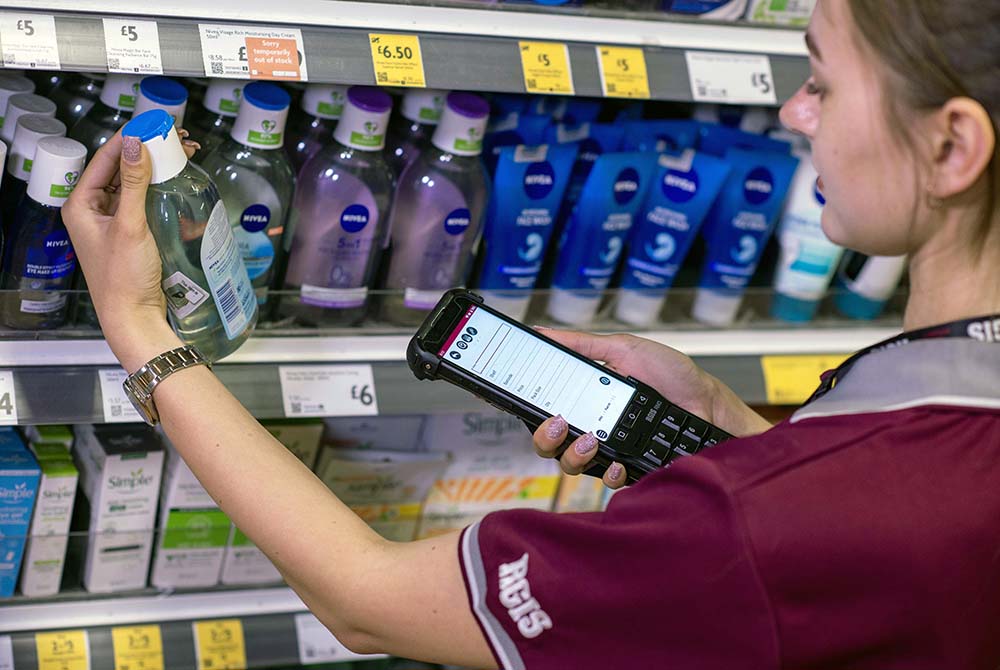

Inventory counting is a time-intensive process, often involving manual counting, scanning of barcodes, or using automated systems. While time-consuming, stocktaking is essential for identifying discrepancies between recorded inventory levels and actual stock. Which can arise due to theft, damage, mismanagement, or system errors. These discrepancies can result in stockouts, overstocking, or financial inaccuracies, all of which are costly to businesses.

Types of Inventory Counting:

- Periodic Counting: Conducted at fixed intervals, such as at the end of a financial year. It provides a comprehensive snapshot of inventory at that point in time.

- Perpetual Counting: A continuous process where inventory is counted regularly (e.g., daily or weekly) in smaller sections. Allowing businesses to maintain a real-time view of stock levels.

- Cyclic Counting: A hybrid approach, cyclic counting focuses on regularly counting specific segments of inventory. Often high-value or fast moving items, to ensure ongoing accuracy in key areas.

Inventory Management: The Strategic Framework

Inventory management encompasses the broader system of overseeing the flow of goods into, through, and out of a business. It involves not only tracking stock inventory levels but also optimizing the purchasing, storage, and distribution processes. The ultimate goal of inventory management is to ensure that the right products are available in the right quantities. At the right time, and in the right condition, all while minimizing carrying costs and avoiding overstocking or stockouts.

A well-executed inventory management strategy aligns with several key business objectives:

– Cost Control: Reducing excess inventory that ties up capital and leads to additional storage and insurance costs.

– Demand Fulfillment: Ensuring sufficient stock to meet customer demand, preventing loss of sales due to stockouts.

– Operational Efficiency: Streamlining procurement and warehousing processes to reduce lead times and optimize the supply chain.

– Data-Driven Decision Making: Leveraging accurate data to forecast demand, adjust reorder points, and manage supplier relationships effectively.

Key Inventory Management Techniques:

- Just-In-Time (JIT): A method where inventory is ordered and received only as needed for production or customer orders, minimizing holding costs.

- ABC Analysis: Categorizes inventory based on importance, with “A” items being the most valuable and requiring frequent monitoring, while “C” items are less critical.

- Economic Order Quantity (EOQ): A mathematical model that helps determine the optimal order quantity that minimizes both ordering and holding costs.

- Reorder Point Formula: A calculation that determines the stock level at which new inventory should be ordered, factoring in lead time and demand rates.

Why Mastering Inventory Counting and Inventory Management Matters

Effective inventory counting and inventory management directly impact a business’s bottom line, customer satisfaction, and operational agility. Let’s explore the specific reasons why these processes are vital to success:

1. Financial Accuracy

Accurate stocktaking ensures that the financial records of a business reflect the true value of inventory, which is a critical component of a company’s assets. Misreporting stock levels can distort financial statements, potentially leading to incorrect tax reporting, misleading investors, and poor financial decision-making.

2. Customer Satisfaction

Customers expect timely delivery of products, especially in industries like retail, e-commerce, and manufacturing. Poor inventory management leading to stockouts or delayed shipments can result in lost sales, customer dissatisfaction, and damage to brand reputation.

3. Cost Control and Efficiency

Efficient inventory management helps businesses reduce excess inventory and avoid carrying unnecessary stock, which can lead to high storage costs, product obsolescence, and wasted resources. In the same way, too little stock increases the risk of stockouts and emergency restocking, which often involves paying a premium for quick orders or lost revenue from missed sales opportunities.

4. Data-Driven Forecasting

Modern inventory management systems leverage real-time data from inventory couting efforts to provide insights into consumer behavior and market trends. These insights help businesses forecast future demand more accurately, reduce safety stock levels, and fine-tune purchasing strategies. For businesses operating in rapidly changing industries, having this agility is critical to staying competitive.

5. Mitigating Risk

Regular inventory counts allows businesses to spot signs of shrinkage (theft, loss, or damage) early on. While effective inventory management can anticipate fluctuations in demand or supply chain disruptions. By addressing these issues proactively, companies can avoid costly operational surprises.

The Future of Inventory Management: Automation and AI

With the advent of technologies such as barcode scanning, radio frequency identification (RFID), and artificial intelligence (AI), both inventory counting and inventory management are becoming more automated and data-driven. Automated inventory tracking systems reduce human error, while AI can predict inventory needs based on historical data, market trends, and even weather patterns.

By integrating automation tools, companies can move beyond traditional inventory counting to perpetual inventory systems, where real-time data updates are constantly feeding into a centralized management platform. This means fewer manual counts and more proactive decision-making, driving efficiency across the supply chain.

Conclusion

Inventory counting and inventory management are the cornerstones of a well-run business. While inventory counting ensures that the physical count of inventory matches the records, inventory management provides the strategic framework to optimize the flow of goods, reduce costs, and ensure customer satisfaction. In an era of rapid technological advancement, businesses that embrace automation, data analytics, and real-time tracking will find themselves better positioned to navigate challenges and seize opportunities in an increasingly competitive marketplace. By mastering these interconnected processes, companies can not only improve their financial health but also foster long-term operational success.